PRODUCTS/ Details

Wedge Wire Screen

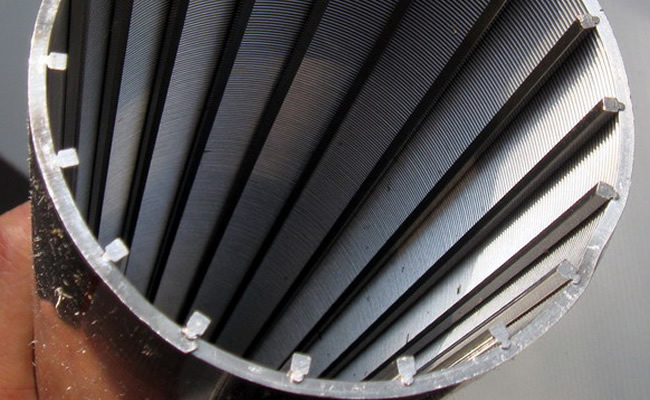

Wedge Wire Screen mostly refers to V - Wire Water Well Screen.

Welded Wedge Wire Screen are made from V shaped profile wire, which is spirally wound around a cage of longitudinal support rods. Each intersecting point of these wires is fusion welded, with an unique welding process. The pitch of winding gives different spacing between two adjacent turns of wire. This spacing gives passage for water to enter. The entire process is completed on fully computerized machines. Wedge Wire Screen offers great strength, precision, long service life and a wide range of applications in the field of process and engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

Advantages including:

Wedge Wire Screen has a continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone (the aquifer) .

A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.

Typical Specifications:

Diameter Available: 1.5", 2", 3", 4", 6", 8", 10", 12", 14"

Slot (mm): 0.15,0.25, 0.50, 0.75,1.00,1.50,2.00,3.00

Lengths: 6 Mts. & 3 Mts.

Material:

Low Carbon Galvanized Steel ( LCG ) and Stainless Steel ( SS-304 )

Application:

- Separating;

- Sizing;

- Straining;

- De-watering;

- Filtering;

- Drying;

- Water intake;

- Media retention.

Products

- Cylindrical Filter Elements

- Pleated Filter Elements

- Sintered Filter Elements

- Stainless Steel Wire Mesh

- Dutch Wire Cloth

- Stainless Steel Crimped Wire Mesh

- Perforated Metal Mesh

- Wrought Iron Guardrail

- Gabion Box

- Checker Plate

- Wedge Wire Screen

- Perforated Metal

- Mining Sieve

Sales Manager: MARY SHEN

Skype ID: mary.shen55

WhatsApp: 86 138 3188 3802

Office Calling: +86 318 782 5222